11 Steps to Smarter Purchase Order Processing

11 Steps to Smarter Purchase Order Processing

If your accounting department is constantly pressed for time and your stakeholders are always chasing down supply orders, your purchase order processing system likely has deeper issues. Manual workflows create costly inefficiencies, including everything from errors and compliance gaps to missed savings and operational delays. Point blank: It’s time to build a better system.

Creating a more organized and optimized purchase order (PO) process strengthens your entire procurement function. It helps your company save money, justify purchases, enforce spending rules, and use procurement data to refine budgets and buying standards.

Learn everything you need to know about improving your purchase order processing methods.

Download the free tool: Purchase Order Template

Purchase order processing steps from end to end

PO processing can feel complex and fragmented, but it doesn't have to be. Use these purchase order process steps to help you build or refine your buying process for better results and savings.

1. Identify needed items

The first step in developing an organized purchase order process is to research and select the necessary supplies from new or existing vendors. Stakeholders should review product information, compare costs, and evaluate similar options across suppliers.

Use your procurement policy to guide product decisions and ensure buyers follow the rules governing spending on goods and services. Well-documented and communicated policies help increase compliance with both internal and external requirements.

You can improve this process by involving department leaders to assess and prioritize what they need. Procurement solutions can also enhance collaboration and enable faster decision-making during needs identification.

2. Create a purchase requisition for the items

The next step is to complete a purchase requisition for the required items. Include all information about the vendor(s) and any supporting documentation approvers will need to move the purchase forward.

A documented purchase order approval process and designated interdepartmental approvers make the procurement process more efficient. Well-defined approval roles eliminate confusion about who needs to review what and why, creating faster transaction timelines and clearer communication between all parties. Additionally, knowledgeable and experienced approvers reduce the likelihood of mistakes or miscalculations, leading to more informed decisions.

3. Submit the purchase requisition for approval

Once you complete the requisition or intake form, submit the order request to the first approver, usually a direct manager or department head. This approver reviews the request, checks it against the department or project budget, and provides initial sign-off. From there, the request routes through other required approvals. Depending on the purchase, it may be subject to review by the IT, legal, security, or finance team.

You may also want to establish spending thresholds that trigger additional checks. For instance, you might require executive approval for contracts exceeding a specific dollar value. Include these thresholds in your procurement software and communicate them clearly to all staff so everyone understands the process.

4. Create an approved purchase order

Once the request has gone through all necessary approvals, the purchasing department uses the requisition form to create a purchase order. A complete purchase request results in a thorough purchase order.

As a legally binding agreement, every PO should include the following information to ensure timely fulfillment and contract compliance:

- Purchase order number

- Date and time of purchase order

- Requestor name and department information

- Vendor information, including name, address, and contact information

- Description of goods or services

- Quantity of goods or services

- Unit price per item

- Total price

- Taxes and fees

- Shipping and delivery information (including cost if applicable)

- Billing instructions to the vendor

- Payment information and net terms

- Additional notes from stakeholders or the finance team

5. Approve and submit the purchase order

In some cases, the procurement, accounting, or finance team may conduct a final review to confirm the purchase order's accuracy and completeness. Once approved, they send it to the vendor. At this stage, the purchase order becomes an open purchase order since it's been issued but not yet fulfilled.

The supplier now reviews the order, confirms item availability, and contacts you or your team with any questions. If certain items are unavailable or won't arrive within the required timeframe, they may offer replacements or provide an updated timeline.

6. Vendor acknowledges and fulfills the purchase order

After accepting the order, the vendor provides an estimated delivery date and shipment tracking number, then begins fulfillment. Once shipped, you can check the order’s status until it arrives.

7. Receive and reconcile goods

When the order arrives, inspect it to confirm all items are present and in good condition. If anything is missing, incorrect, or damaged, contact the vendor to request a replacement, refund, or—in extreme cases—refuse the shipment altogether.

Once you confirm receipt, the accounting team creates a receiving record and notes any delivery exceptions or compliance issues.

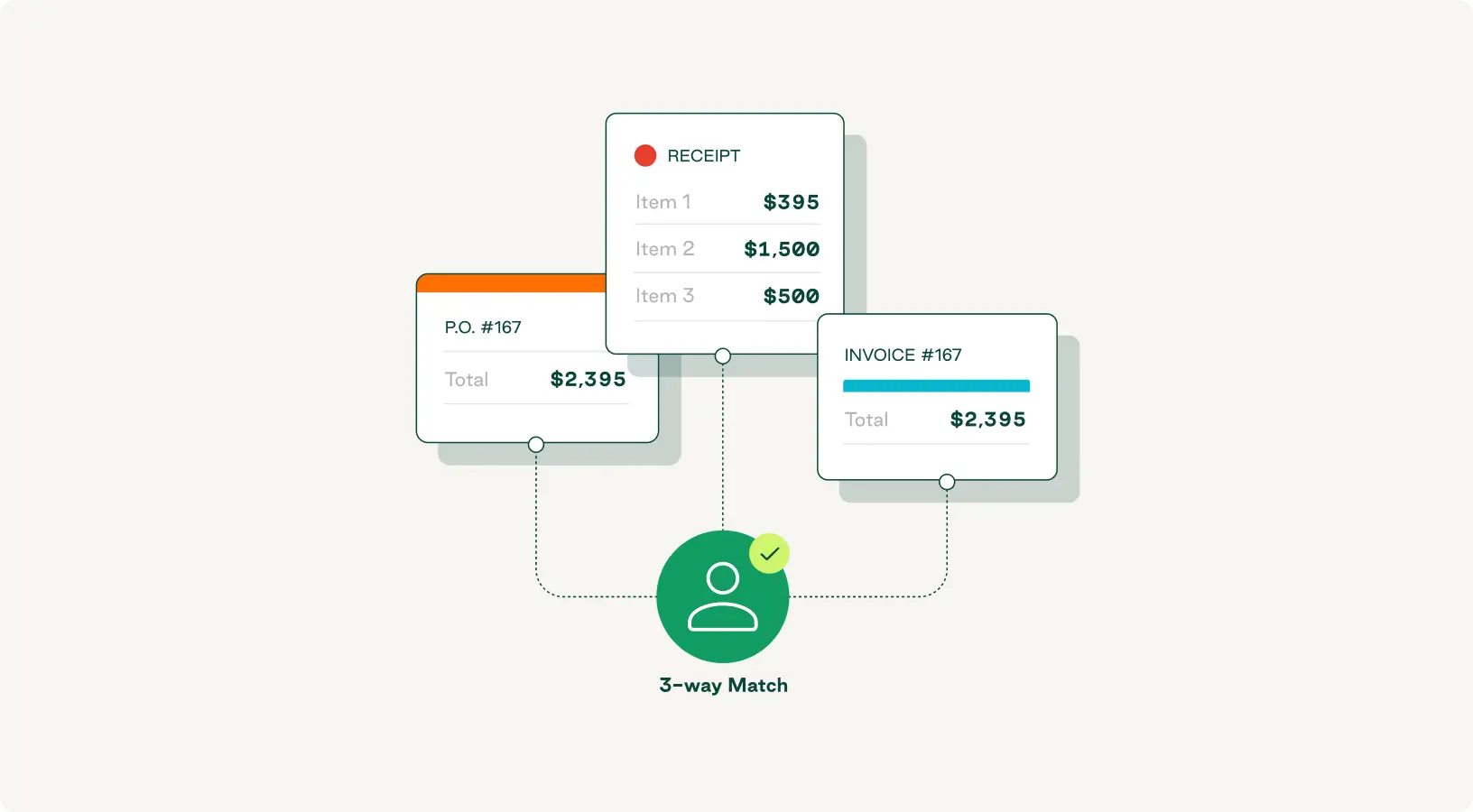

8. Complete three-way matching and invoice verification

Next, the accounting team performs a three-way match by comparing the purchase order, receiving record, and vendor invoice to confirm consistency in pricing, payment terms, and quantities. If there are discrepancies, you'll need to investigate and resolve them before processing payment.

While this step is essential, it can be tedious and prone to errors. A centralized procurement platform can reduce manual work, improve document alignment, and help your team complete verifications more quickly.

9. Process payment and close purchase order

After a successful three-way match, your accounts payable team can process the payment. Depending on the agreed-upon terms, they might make payment by check, ACH, credit card, or another approved method. Once the payment is complete, you can mark the PO as closed.

10. Ensure accurate record-keeping

Closing the purchase order doesn't end the process. Maintain an accurate audit trail by keeping records of all related activity, including requisitions, approvals, POs, delivery receipts, invoices, and payment confirmations. Store this information in a centralized location so you can easily analyze it for internal reviews, process improvements, or external audits if necessary.

11. Review supplier performance

The final step of purchase order processing is evaluating supplier performance. Collect feedback from stakeholders about the accuracy, timeliness, and quality of the goods or services delivered. Use this data to assess vendor reliability and determine whether you trust the partnership to support your organization as it scales.

Your procurement team can use this information to improve future purchasing decisions, strengthen supplier relationships, and enhance the overall procurement process.

The disadvantages of a manual PO processing workflow

Processing purchase orders manually introduces several avoidable challenges, including:

- Errors and delays: Manual data entry increases the risk of mistakes, such as duplicate orders, incorrect quantities, and misfiled documents. These can delay the procurement process and disrupt operations.

- Gaps in compliance and audit readiness: Managing documentation by hand makes it harder to meet audit requirements. Without a centralized digital record, it's difficult to track actions, organize documents, and generate the reports needed for compliance.

- Higher costs: Inefficient manual workflows often lead to missed early payment discounts, late fees, and unnecessary purchases, all of which increase overall procurement costs.

- Difficulty scaling purchases and operations: As your business grows, manual processes become harder to manage. Automated software makes it easier to handle higher order volumes and maintain control over spending.

- Limited visibility and reporting: Tracking orders in spreadsheets or outdated systems makes it nearly impossible to access real-time data. Without clear insights, you might miss duplicate purchases, exceed budgets, or overlook vendor performance issues.

By combining automation technologies with best practices, you can eliminate manual bottlenecks and build a more efficient, scalable purchase order system.

Benefits of automating the purchasing process

Automating purchase orders ensures accuracy throughout the purchasing process and improves the entire procurement workflow. A few of the biggest benefits of automating your purchase order process include:

- Better cost savings: Prevent missed payments, overcharges, and invoice discrepancies. With automation, you get full visibility into where every procurement dollar is going.

- Greater accuracy: Eliminate errors in financial tasks like invoice reconciliation, payment processing, and PO matching. Automating critical accounting processes ensures every transaction is accurate and auditable.

- Reduced manual entry: Minimize errors and save time by removing tedious manual steps. Errors often lead to processing exceptions that require research and may lead to incorrect or misapplied payments.

- Enhanced reporting: Leverage PO automation to make creating reports on ordering and spending patterns easy. Reporting can provide the visibility to inform future spending decisions, benchmark competitive pricing, and strengthen supplier relationships.

- Reduced risk: Use automation to apply user access controls, track activity, and enforce approval rules. Software also helps prevent unauthorized payments or purchases and improve procurement security.

- Stronger supplier relationships: Gain a comprehensive view of procurement activity and costs. Performance data can help you negotiate better deals and build stronger long-term supplier partnerships.

Best practices for efficient PO processing

To get the most out of your purchase order system, reinforce it with a few best practices. These steps can help you reduce risk, improve efficiency, and increase savings.

Build a documented procurement process

Establishing clear procurement policies helps maintain budgetary control and ensures consistent purchasing. By defining who's authorized to make purchases, setting spending thresholds, and outlining vendor requirements, you can reduce maverick spend, improve compliance, and create a more efficient procurement workflow.

A recent Ivalua and Procurious procurement study found that 74% of procurement leaders have significantly reworked their procurement strategies in response to recent challenges, making policy documentation more important than ever. Solid documentation supports more accurate budgeting, provides a clearer picture of supply spending over time, and safeguards against acts of fraud, especially when partnering with new vendors.

Create a departmental approval roster

Departmental purchase approval hierarchies are crucial for maintaining procurement oversight and ensuring purchases align with the company's strategy and financial objectives. They help improve accountability, speed up approvals, and minimize waste while supporting operational needs.

Establish a preferred vendor network

A preferred vendor network is a shortlist of pre-approved, high-quality partners buyers can rely on for their procurement needs. Using preferred vendors increases efficiency while reducing third-party risk. It also allows businesses to leverage bargaining power when negotiating per-item prices, volume discounts, and purchase terms.

Use strategic sourcing methods

Strategic sourcing takes a structured, data-driven approach to purchasing. By analyzing market trends and segmenting suppliers, you can optimize pricing, ensure higher-quality goods and services, and work with vendors who align with your business needs. Using a strategic vendor sourcing approach enhances your procurement process and supports long-term supplier partnerships, which is especially critical when navigating supply chain disruptions.

How Order.co facilitates PO processing

Order.co is a comprehensive procurement management platform that unifies the entire purchasing workflow—from requisition through delivery and reporting. Unlike traditional solutions that simply send off digital purchase orders, it actively manages each step of the process to improve speed, accuracy, and visibility.

Order.co offers features that make every step of procurement faster and easier:

- Centralized purchasing and vendor management: Manage all vendors and purchases from one platform with full visibility across departments.

- Automatic PO creation and submission: Eliminate repetitive manual tasks and reduce the risk of human error.

- Customizable approval workflows: Set custom approval paths that align with your budgets, roles, and departments.

- Easy item selection and reordering: Use vendors you already know and trust via a Chrome add-on that enables in-browser cart additions.

- Dynamic purchasing guidelines and spend limits: Apply buying parameters and limits based on user, role, department, location, and more.

- Automatic GL coding and three-way matching: Ensure accurate records and faster reconciliation with automated back-end accounting support.

Schedule a demo with Order.co to learn how you can unify the entire procurement process to reduce costs, scale purchasing, and stay compliant.

Get started

Schedule a demo to see how Order.co can simplify buying for your business

"*" indicates required fields