Procurement Analysis: Complete Guide to Strategic Purchasing

Procurement Analysis: Complete Guide to Strategic Purchasing

To launch successful procurement initiatives, stabilize cash flow, and uncover savings, procurement teams need a clear view of every step in the procure-to-pay (P2P) cycle—from sourcing to settlement. Top teams rely on procurement analysis as an essential part of their strategy, using it to answer questions quickly and efficiently, gain better control over projects, and identify real cost-saving opportunities.

This guide breaks down everything you need to know about procurement analysis: what it is, how often to conduct it, and how it can boost savings and productivity. It also shares best practices you can start using immediately to begin seeing positive impacts.

Download the free tool: Procurement KPI Tracker Template

What is procurement analysis?

Procurement analysis is the process of examining your company's spending to understand where your money is going and how to control it. It helps you anticipate costs, turn information into actionable insights, and make more informed decisions.

Well-visualized procurement data can show you:

- What the company is spending on goods

- How your spend compares to market benchmarks

- Where to secure the best deals on future purchases

- How to manage cash flow and improve your financial performance

Procurement analysis brings a data-driven approach to vendor selection and purchasing, drawing on past performance, current market data, and predictive insights to guide more informed decision-making. It's a bit more technical than a crystal ball, but when done correctly, it works like magic.

Examples of the different types of procurement analytics

You can categorize procurement analytics into four main types: descriptive, diagnostic, predictive, and prescriptive. Each offers a different lens on purchasing, and together they provide a complete view of performance.

Descriptive analytics

Descriptive analytics answers the question, "What happened?" It summarizes historical data to reveal spending patterns and establish performance baselines.

Key metrics include:

- Total spend by category, supplier, and department

- Purchase order volume and average order value

- Contract compliance rates

- Historical supplier delivery performance

Diagnostic analytics

Diagnostic analytics goes deeper to explain why certain outcomes occurred. It uncovers the root causes behind procurement results and spending anomalies.

Key metrics include:

- Variance analysis comparing budgeted vs. actual spend

- Maverick spending identification

- Drivers of supplier performance issues

- Purchase order cycle time delays

Predictive analytics

Predictive analytics looks ahead, using statistical models and machine learning to forecast market trends and make more proactive decisions. Teams using predictive analytics report 25–40% faster response times to supply chain disruptions.

Key metrics include:

- Demand forecasting accuracy

- Price trend predictions

- Supplier risk scores

- Inventory optimization projections

Prescriptive analytics

Prescriptive analytics answers "What should we do?" It combines predictive insights with optimization algorithms to recommend the best procurement strategies.

Key metrics include:

- Optimal reorder points and quantities

- Recommended supplier allocations

- Contract negotiation timing

- Sourcing strategies

What are the business benefits of procurement analysis?

Procurement analysis isn't just for large corporations—vendor spending often makes up 40-80% of total costs, so every business can benefit from keeping a close eye on it.

A strong procurement analytics process can help you:

- Improve spend management: Consolidate fragmented purchasing data across departments to see total spend by category. This visibility helps you allocate budgets more effectively and makes it easier to spot opportunities to negotiate volume discounts with preferred suppliers.

- Increase profitability: Uncover cost-saving opportunities through supplier rationalization, contract optimization, and early payment discounts to directly improve bottom-line margins. You can reinvest these savings in strategic initiatives that drive revenue growth.

- Establish performance metrics: Set standardized procurement KPIs, such as cost per purchase order, procurement cycle time, and contract compliance rates. These benchmarks help you track progress and demonstrate procurement's value to stakeholders.

- Evaluate supplier performance: Use data on on-time deliveries, quality defects, responsiveness, and pricing competitiveness to assess suppliers objectively. Evidence-based insights and constructive feedback support better sourcing decisions and strengthen supplier relationships.

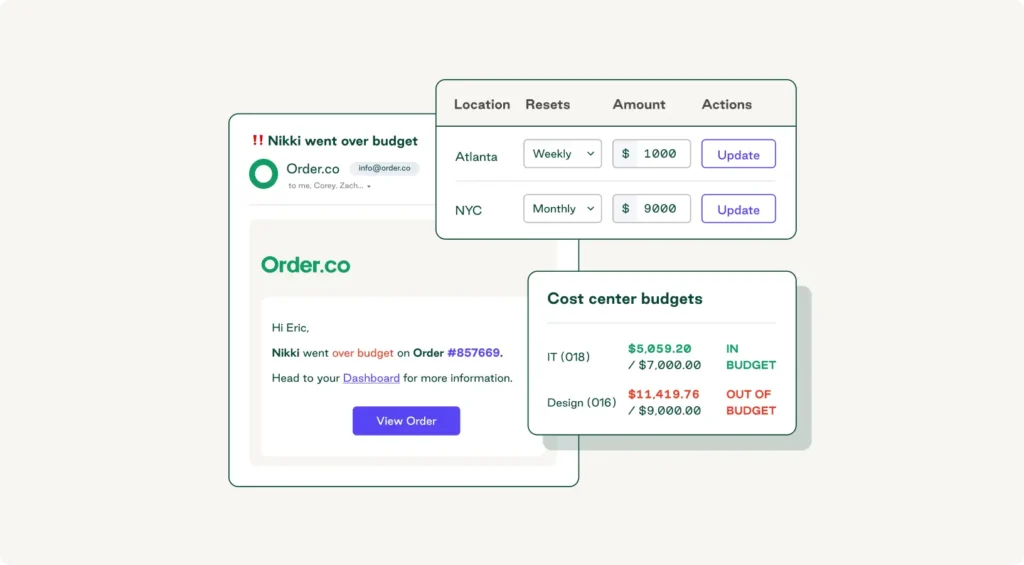

- Identify cash leaks and savings opportunities: Detect maverick spend, duplicate payments, and non-compliant purchases as they happen. Real-time dashboards alert you to price variances and expiring contracts, preventing missed savings opportunities. with considerably less friction.

What does the procurement analytics process involve?

The procurement analytics process involves turning raw procurement data into actionable insights that drive smarter purchasing decisions. It begins with collecting information from data sources like ERP systems, procurement platforms, supplier portals, and market intelligence databases. Organizations that deploy large-scale P2P software often see up to 60% improvement in spend visibility and management.

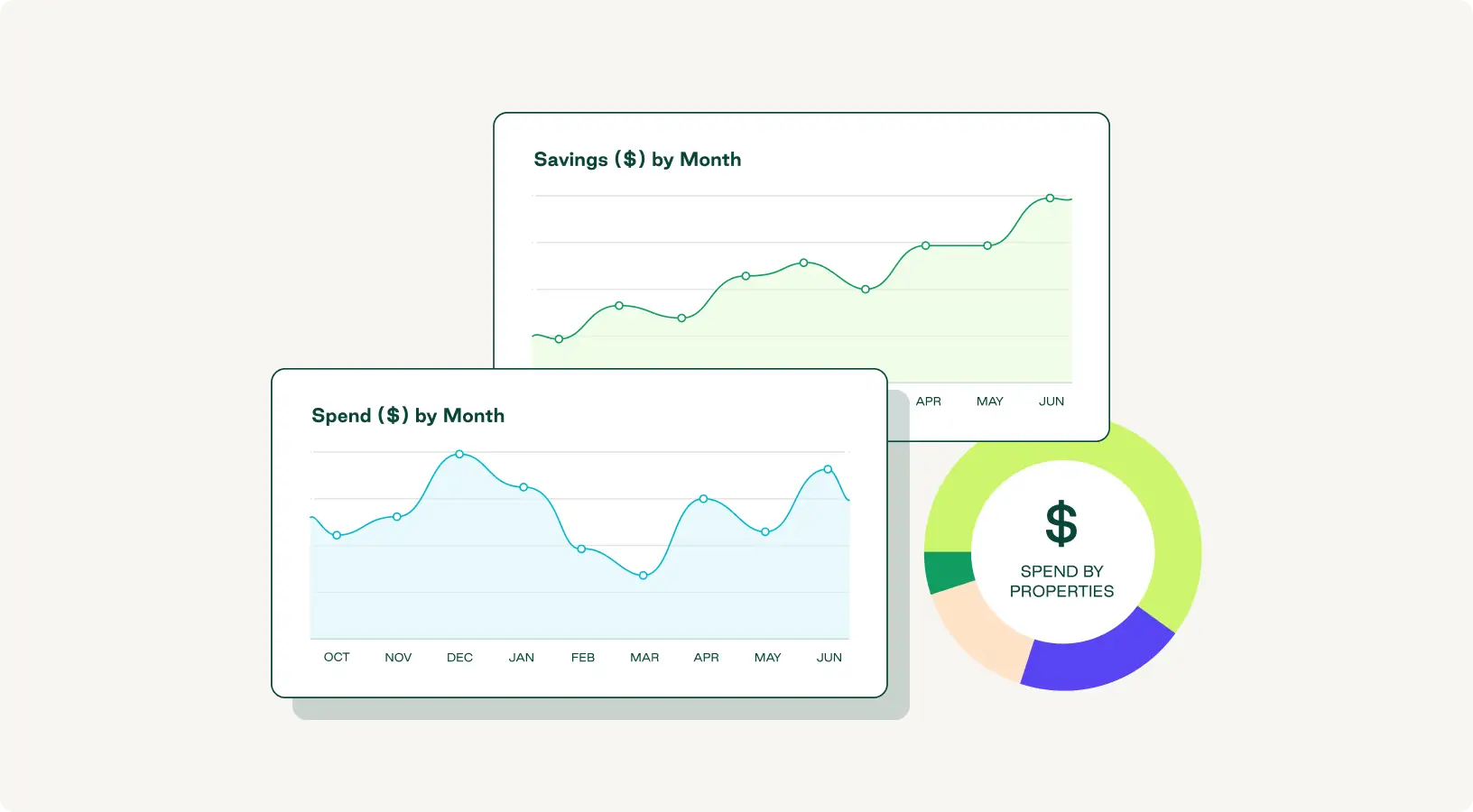

Once collected, the data is cleansed and classified to standardize categories and ensure consistency and accuracy across departments. Next, teams conduct spend analysis to uncover spending patterns, assess supplier performance, evaluate contract compliance, and analyze market conditions. They then visualize and report these insights through dashboards and executive summaries, making the information clear and accessible to stakeholders at all levels. Finally, teams act on the findings, identifying cost-saving opportunities, negotiating better supplier terms, optimizing inventory levels, and implementing process improvements to reduce procurement costs.

How often should you do a procurement analysis?

How often you should run a procurement analysis depends on your business cycles, spending volumes, and risk profile. Most organizations benefit from a tiered approach that combines regular scheduled reviews with event-triggered data analysis.

Monthly monitoring is ideal for focusing on high-priority categories, major suppliers, and key performance indicators. Regular check-ins help you course-correct and keep procurement aligned with broader business objectives.

Quarterly reviews work well for comprehensive spend analysis and supplier performance evaluations. This cadence provides enough data to spot meaningful trends and implement improvements between reviews.

Annual strategic analysis supports big-picture procurement benchmarking against industry standards, comprehensive category reviews, and the development of long-term sourcing strategies.

In addition to routine reviews, several triggers call for ad-hoc analysis, including:

- Major market changes, such as commodity price fluctuations or currency exchange rate shifts

- Supplier performance issues like quality problems, delivery failures, or financial distress

- Budget variances that exceed set thresholds

- New product launches or business expansions that require different sourcing strategies

- Regulatory changes that impact compliance requirements or trade policies

- Supply chain disruptions from geopolitical events, natural disasters, or capacity constraints

Who should be involved in the procurement analysis process?

Procurement analysis works best when it’s a team effort. While procurement leaders typically take charge, success depends on input from across the organization:

- Procurement team: Owns the process, from data collection to insight generation. Their deep understanding of sourcing strategies and supplier relationships provides essential context.

- Finance team: Contributes budget data and cost insights as well as financial impact assessments. They validate cost-saving calculations and ensure analysis aligns with financial reporting requirements.

- Category managers and business unit leaders: Provide operational context, validate findings, and help prioritize improvement opportunities based on business needs.

- Supply chain and procurement operations teams: Offer insights into inventory management, demand patterns, and logistics factors that impact procurement decisions.

- Executive leadership: Reviews summarized findings and participates in strategic decision-making, particularly for high-value categories or significant process changes.

- IT and data analytics specialists: Maintain data infrastructure, ensure system integrations function properly, and provide advanced analytical capabilities for complex modeling when needed.

Analysis results should be shared across the entire organization. While procurement leads the effort, finance applies insights to budgeting, and operations teams use them to adjust production planning. Business units incorporate these insights when aligning purchasing with strategic objectives.

What procurement analysis challenges might you encounter?

Even with advanced tools and organizational buy-in, procurement analysis comes with common hurdles that can slow progress or limit impact.

Common procurement analysis challenges include:

- Data quality and integration issues: Procurement data often lives across multiple systems with inconsistent formats, incomplete records, and duplicate entries. It takes significant effort to cleanse and normalize this data before meaningful analysis can begin.

- Lack of standardized processes: When departments use different suppliers, approval workflows, and categorization schemes, consolidating procurement data becomes difficult and time-consuming.

- Limited analytical skills: Even with improved data access, many procurement professionals still lack expertise in statistical analysis, data visualization, or predictive modeling techniques.

- Resistance to change: Analysis findings can challenge existing supplier relationships or established practices, causing stakeholders to dismiss data-driven recommendations that conflict with their experience or preferences.

- Technology limitations: Legacy procurement systems may lack advanced reporting features, require manual data extraction, or fail to integrate with modern analytics platforms.

- Resource constraints: Smaller teams often struggle to balance analytical work with day-to-day operational demands, limiting how frequently and comprehensively they can conduct analyses.

Overcoming these challenges requires the right mix of technology, governance, and culture. Investing in integrated procurement platforms, data quality standards, and analytical training while fostering a culture that values evidence over mere intuition helps unlock the full potential of procurement analysis.

7 best practices for saving on purchasing costs

If your company struggles with budget overruns and untracked purchasing, these seven best practices can help you optimize spend and strengthen your bottom line.

1. Formalize your procurement spend process

The first step to cutting costs is standardizing your procure-to-pay process. A formalized procurement function details how to move from requisition to payment, establishes set spending rules, fosters accountability, and forms the foundation for effective contract management.

For example, establishing a process was one of the first steps to savings for NY Kids Club. The company used Order.co to replace its inefficient, email-based purchase order system and get a handle on spending across its 19 locations. Automating the process eliminated wasteful spending, improved cash flow, and saved 1,325 hours on manual tasks annually.

2. Increase your procurement data visibility

Saving requires visibility. A modern, automated procurement analytics platform helps you see exactly where your money is going—by category, department, product type, supply base, tax nexus, or location. This transparency moves you beyond basic “revenue minus expenses” reporting to real-time, actionable spend intelligence.

Once your spend data is extracted and refined, a P2P platform can display it in dashboards that make insights easy to understand and apply, helping you continuously refine your procurement strategy.

3. Build strategic supplier relationships for sourcing goods

Strong vendor partnerships can help you realize cost savings and operational efficiencies. By consolidating spend with preferred suppliers for high-volume and recurring purchases, you open the door to volume discounts and more flexible terms.

Relying on strategic vendor partnerships also saves time by reducing repetitive due diligence and the tasks associated with bringing on a new vendor. With a curated preferred vendor list and a solid supplier management process, you can buy smarter and with less friction.

4. Stabilize your inventory and sourcing practices

Inefficient sourcing and poor inventory control can cut into profits in multiple ways. Delivery delays, stockouts, or rush orders often lead to expedited shipping fees, quality issues, and invoice errors.

A centralized P2P system like Order.co simplifies procurement by automating purchase requests, sourcing, and approvals while providing real-time visibility into spend data and order statuses. While it does not directly track inventory levels, Order.co integrates with most major ERP and accounting systems to help you connect purchase activity with inventory management, supporting more informed buying decisions and greater supply chain responsiveness.

5. Identify cash leaks with spend analysis

Once you have a structured process in place, it becomes easier to uncover inefficiencies and prevent waste.

Common cash leak sources include:

- Non-preferred vendor use: When employees purchase from whichever supplier they want, they may miss out on negotiated discounts that would save the company money.

- Maverick spending: A lack of visibility means buyers order first and ask questions later. By centralizing your procurement process, you eliminate the occurrence of one-off, corporate card, and unplanned purchases that drive up costs.

- Overordering or duplication: Decentralized ordering across departments or locations can lead to duplicate orders and reduce leverage on volume pricing. Centralizing orders allows you to track total costs across sites, avoid unnecessary purchases, and apply strategic sourcing to save money.

6. Use AP automation to eliminate mistakes and busywork

Manual purchase-to-pay (P2P) process administration creates risk. Missed payments, duplicate entries, and mismatched data can lead to late fees, delays, and unnecessary reconciliation work.

Automating supplier invoicing, reconciliation, and payments reduces human error and administrative overhead, improving accuracy and efficiency. By minimizing repetitive tasks, you free your teams up to focus on more meaningful projects.

7. Simplify your sourcing and payment process with Order.co

To apply all these money-saving practices effectively, you need a unified platform that brings your procurement data and processes together. With Order.co as your P2P system, you can build a purchasing workflow that reduces cash leaks and rogue spending, connects you with the best suppliers and prices, speeds up approvals, and simplifies payments using automated reconciliation and invoice batching.

If you’re ready to realize cost savings and boost revenue with smarter workflows and actionable analytics, schedule a demo to see Order.co in action.

FAQs

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields