3 Key Strategies for Supplier Performance Management Success

3 Key Strategies for Supplier Performance Management Success

Managing suppliers effectively isn't just a procurement task—it's a competitive advantage. When suppliers consistently deliver high-quality products on time and within budget, your entire supply chain runs more smoothly. When they don't, costs rise, timelines slip, and you spend valuable time putting out fires.

A strong supplier performance management (SPM) framework helps you stay ahead of these challenges. By creating clearer expectations and surfacing problems earlier, it supports better working relationships with the suppliers you rely on most.

With the fundamentals of SPM in place, you can focus on the metrics that actually matter, tackle underperforming suppliers before small issues grow, and use technology to manage your vendor relationships efficiently—even as your business scales.

Download the free tool: Vendor Scorecard Template

What is supplier performance management?

Supplier performance management is the systematic process of measuring, analyzing, and improving how well suppliers deliver on agreed-upon standards. Rather than simply tracking whether invoices match purchase orders, effective SPM evaluates suppliers across multiple dimensions, including quality, delivery reliability, cost accuracy, compliance adherence, and responsiveness.

The core objectives of SPM are simple:

- Ensure suppliers meet contractual commitments

- Identify risks before they disrupt operations

- Drive continuous improvement through data-driven feedback

- Build stronger, more strategic supplier relationships based on measurable data

Yet many companies struggle to get a clear picture of supplier performance. According to supply chain research by KPMG, 43% of organizations have limited or no visibility into tier-1 supplier performance, leaving critical gaps in their operations.

Modern vendor management software like Order.co brings supplier data into one place. By consolidating spend analytics, compliance metrics, and performance insights into unified supplier profiles, it eliminates fragmented spreadsheets, giving procurement teams enhanced visibility into supplier health and trends.

What are the benefits of effective supplier performance management?

Nearly 30% of supply chain disruptions cost over $5 million, putting operations and profitability at risk.

Structured SPM initiatives can help you stay ahead of these disruptions, turning raw performance data into tangible benefits, including:

- Cost savings from spotting pricing discrepancies, reducing emergency purchases from premium suppliers, and negotiating better terms based on performance data

- Improved quality control by catching defects and quality issues early to minimize rework and customer complaints

- Stronger supplier relationships through transparent, data-backed conversations instead of subjective assessments

- Better risk mitigation by keeping tabs on supplier financial health and operational stability to avoid supply chain disruptions before they occur

- Enhanced compliance by tracking certifications, audit requirements, and regulatory adherence across your entire supplier base

- Increased operational efficiency from simplifying performance reviews and reducing time spent on manual data collection

- Competitive advantage through improved supplier performance and reliability that helps you deliver products more consistently

Which metrics should you track to measure supplier performance?

Selecting the right procurement key performance indicators (KPIs) ensures you're focusing on what truly impacts your business. Order.co offers customizable KPI dashboards that make it easy to monitor these metrics so you can spot trends quickly.

On-time delivery and order accuracy rates

On-time delivery (OTD) measures whether suppliers ship orders by the agreed date, directly impacting your ability to meet customer commitments. Order accuracy tracks whether you receive the correct items in the right quantities.

When suppliers make frequent mistakes, it cascades through your operations—creating delays, increasing handling costs, and frustrating both internal teams and end customers.

Quality defect rates and return/rework costs

Defect rates reveal how often products fail to meet quality standards, with high rates signaling underlying issues with supplier processes, materials, or controls. Tracking the percentage of defective units received helps you quantify quality issues and focus your supplier evaluation efforts on the vendors who need the most attention.

Return and rework costs add hidden expenses. When you have to send back faulty goods or repair defective items, you're not just paying for the product twice—you're also absorbing labor, shipping, and opportunity costs.

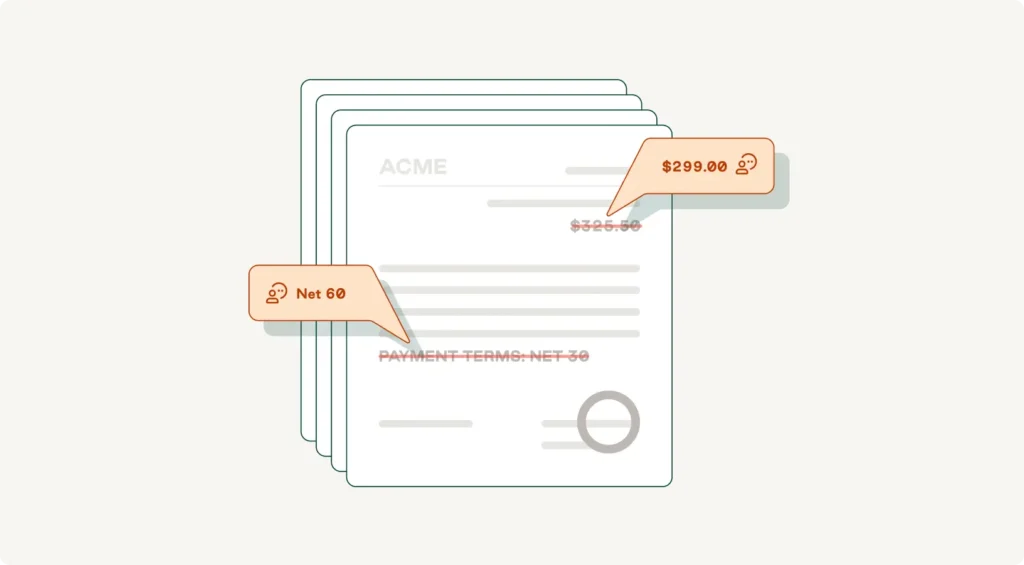

Cost variance and spend forecast accuracy

Cost variance measures the difference between contracted prices and actual invoices. Significant variances can indicate pricing errors, unauthorized charges, or suppliers failing to honor negotiated rates—directly impacting your bottom line and budget predictability.

Spend forecast accuracy shows how consistent suppliers are with costs so you can plan budgets more effectively and identify opportunities for better negotiation or consolidation.

Compliance adherence and risk scores

Compliance metrics track certifications, safety protocols, environmental standards, and regulatory requirements. In industries with strict regulations, supplier non-compliance can result in fines, legal liability, or reputational damage.

Risk scores combine factors like financial health, geographic concentration, delivery consistency, and incident history to highlight warning signs early, allowing you to create contingency plans before problems occur.

3 strategies to improve underperforming suppliers

Even well-managed supplier portfolios include providers that occasionally fall short of expectations. When underperformance goes unaddressed, it can erode margins, damage customer relationships, and create supply chain vulnerabilities that competitors can exploit.

If a supplier isn’t meeting expectations, the following three strategies can help you address performance gaps and protect your operations.

1. Collaborative remediation plans and SLA renegotiation

If a supplier misses a target, begin with a structured root cause analysis. Schedule a joint review meeting to understand what's driving the performance gaps. Is it a capacity issue? A quality control problem? A communication breakdown?

Work together to create a detailed remediation plan with clear milestones, deadlines, and accountability measures. Update service level agreements (SLAs) to reflect realistic but ambitious goals, and include escalation protocols so both parties understand what happens if performance doesn’t improve.

Vendor scorecards provide the framework for tracking progress against these plans, helping you monitor improvements and, if necessary, implement corrective actions like increased oversight, temporary volume reductions, or formal improvement programs.

2. Incentive programs and continuous improvement workshops

Positive reinforcement often works better than penalties alone. Reward suppliers for exceeding performance thresholds through preferred supplier status, increased purchase volumes, faster payment terms, or recognition programs.

Another way to drive continuous improvement is through collaborative workshops. These sessions allow you to share best practices and teach new techniques, and you can invite top performers to mentor struggling suppliers. This helps foster a community of excellence across your supply base while strengthening relationships.

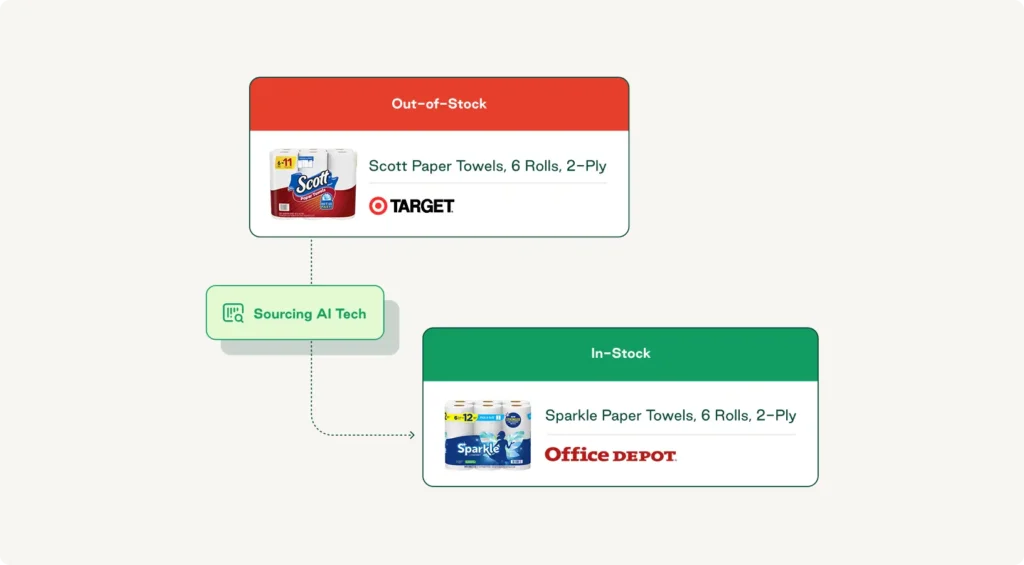

3. Dynamic spend reallocation and secondary sourcing

If remediation efforts stall, protect your operations by using performance data to guide spend allocation. Identify which suppliers consistently meet expectations and which underperform, then gradually shift volume toward top performers while giving underperforming suppliers a chance to improve.

Maintain a "warm backup" for critical categories so you can quickly redirect orders during disruptions. Supplier segmentation can help you determine which suppliers need backups and which warrant deeper strategic partnerships.

For example, if Supplier A consistently delivers with 98% on-time delivery while Supplier B struggles at 85%, you can move more volume to Supplier A until Supplier B demonstrates sustained improvement.

How do procure-to-pay platforms support supplier performance management?

Modern procure-to-pay platforms make SPM easier and more actionable. By consolidating your supplier data and connecting it with your existing enterprise resource planning (ERP) and procurement workflows, these platforms provide the insights and context needed to monitor performance, spot risks, and make informed decisions throughout the vendor management lifecycle.

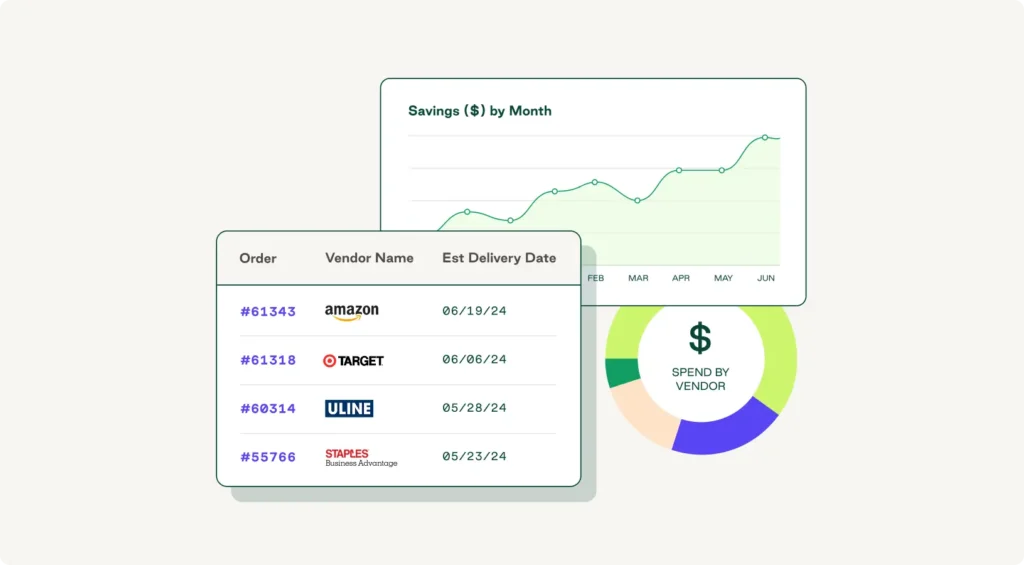

Centralized dashboards

Rather than juggling spreadsheets and multiple systems, platforms like Order.co bring critical supplier and spend information together in one place. Spend by vendor and category, delivery success, and order delays are visible at a glance, helping you identify where suppliers are meeting expectations and where attention is needed.

Spend analytics and vendor scorecards

Scorecards turn raw data into actionable insights, showing performance relative to internal priorities like pricing, compliance, and spend patterns. Order.co spend analysis and reporting tools, paired with the platform's free supplier scorecard template, provide a structured way to evaluate suppliers, benchmark performance, and spot trends across your vendor base.

Workflow support and context

Threshold-based alerts help you stay on top of potential issues. Order.co connects supplier performance insights to your broader procurement management processes to provide the context you need to review performance, follow up on problems, and make smarter sourcing and contract decisions.

Comprehensive supplier information management

No single system captures every data point. Order.co supports supplier information management by providing complete visibility across spend by vendor, product availability, and order statuses. This gives you a clear view of supplier health—useful for audits, onboarding, and keeping everyone aligned.

Improve your supplier performance management with Order.co

Fragmented supplier data, manual performance tracking, and reactive problem-solving create unnecessary costs and risks. When you lack visibility into supplier performance, even minor issues can cascade into major disruptions that impact customers and damage your competitive position.

Order.co can help you address these challenges by providing:

- Unified supplier profiles that consolidate performance data, spend analytics, and product information in one centralized location

- KPI tracking that reduces manual reporting and provides clear visibility into supplier health across your vendor base

- Workflow support that connects performance insights to procurement processes so you can catch issues before they escalate

Optimize your supplier relationships with Order.co—schedule a demo to see how the platform can help you simplify risk assessments, monitor performance KPIs, and drive procurement excellence.

FAQs

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields